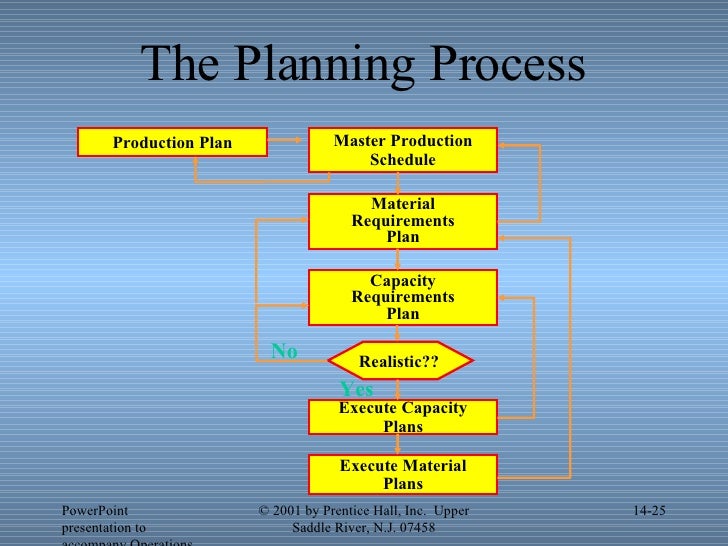

Master production schedule. master production scheduling. it forms the link between production planning and what manufacturing will actually build. it forms the basis for calculating the capacity and resources needed the mps drives the material requirements plan. as a schedule slideshow.... The master production schedule defined mps is the process that helps manufacturers plan which products and related quantities to produce during certain periods. mps is proactive in that it actually drives the production process in terms of what is manufactured and what materials are procured.. Master production scheduling - powerpoint ppt presentation - app links higher-level facility planning to lower level scheduling decisions (crp) material and. capacity plans. app (cont) role of aggregate planning "master production scheduling" is the property of its rightful owner..

Material requirements planning (mrp) is a production planning, scheduling, and inventory control system used to manage manufacturing processes. most mrp systems are software -based, but it is possible to conduct mrp by hand as well.. The master production schedule specifies which end items or finished products the company is to produce, how many are needed, and when they are needed. the numbers that are on the master production schedule represent production, not demand, may be a combination of customer orders and demand forecasts, and gives what needs to be produced.. In production planning and control for material requirements planning, scheduling, and production confirmation processes. bill of material (bom) a bill of material is a complete, formally structured list of the components together with the quantity required to produce the product or assembly..

Tidak ada komentar:

Posting Komentar